A breakthrough in agricultural nanotechnology could help reduce food production losses to pests and pathogens, without the toxicity impacts of current chemical sprays.

Viruses are part of the pest and pathogen burden that reduces food production globally by a massive 20 to 40 per cent, even as an estimated 795 million people – one in nine – do not have enough food to lead a healthy, active life.

That statistic has inspired agricultural scientist Professor Neena Mitter and her UQ colleague Professor Zhi Ping (Gordon) Xu to develop novel crop protection technology, and links with agribusiness partner, Nufarm, will help deliver the new technology to farmers.

Working in QAAFI’s Centre for Plant Science, Professor Mitter explains that currently there is no way to directly protect crops from viruses. Instead, pesticides are used to kill the insects that transmit viral diseases.

“Not only are viruses causing food losses, the chemicals we use to control their insect vectors have toxicity issues to human health, to our waterways from run-off, and to the environment,” she says.

“That was why I started looking at alternative crop protection methods.”

Her new approach involves boosting the plant’s own defences, priming them in the manner of a vaccine to naturally attack specific viruses.

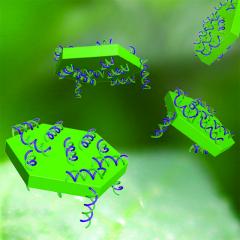

The tools Professor Mitter uses are wisps of genetic material that are sprayed onto the plant. This biological material, however, is extremely fragile. To help stabilise it, she teamed up with nanotechnology experts led by the University of Queensland’s Professor Gordon Xu, based at the Australian Institute for Bioengineering and Nanotechnology (AIBN).

A high tech combination

“The solution involves a combination of nanotechnology and biotechnology ,” Professor Xu says.

“It means we can target any virus – or combination of viruses – that cause crop losses without killing insects and with no toxic effects to humans or the environment.” Professor Neena adds.

No gene modification or DNA is required in their protocol.

The method takes advantage of a quirk in the genetic language of living organisms: namely that all genes – including viral genes – have to be ‘expressed’ to have an effect.

Expressing a gene involves making many molecular copies of the gene’s DNA. These copies take the form of RNA molecules, a chemical cousin of DNA. The RNA copies then serve as the scaffold to make the compounds required for life, such as hormones, enzymes and structural proteins.

Normally, just one strand of the DNA ‘double helix’ is copied, meaning that the plant’s own RNA molecules are single-stranded. In contrast, when viruses reproduce inside a plant, they go through a stage when they produce double-stranded RNA (or dsRNA). Plants have learnt to detect and attack this dsRNA, a natural defence response called ‘gene silencing’.

Nano-clay delivery system

Professor Mitter triggers the plant’s own, gene-silencing defences by exposing the plant to dsRNA made synthetically in the laboratory. Professor Xu’s contribution was to develop a nanoscale ‘clay’ matrix that is ideally suited to protect this dsRNA once it is sprayed onto a crop.

The specially designed matrix forms minuscule, stacked layers that Professor Mitter compares to puff pastry. These degrade naturally, but in the process they dramatically extend the dsRNA’s protective effect.

Bioclay’s commercial application

Global lead for transformational innovation at Nufarm, a worldwide manufacturer of crop protection products, is Mike Pointon, who has closely followed BioClay’s development. Nufarm is undertaking supportive research of its own on the Bioclay product.

Mr Pointon says issues with chemical-based crop protection are increasing worldwide.

“We are seeing the chemical targets evolve resistance, there is regulatory pressure on active ingredients due to toxicity concerns, and the cost of discovery for new chemicals is enormous,” he says.

“That means Nufarm is very interested in new crop protection technology and this research absolutely has the potential to find commercial application.”

BioClay circumvents key problems caused by chemical sprays. There are no toxic compounds or breakdown products associated with BioClay.

It does not leave problematic residues on food. It is applicable across plant crops, from cereals through to horticulture. It is highly specific, affecting only the dsRNA-targeted pathogen. And should resistance emerge, the dsRNA can be tweaked to get around it.

Best of all, Mr Pointon believes that the same approach can be applied to other classes of disease-causing pathogens, such as fungi.

“The main hurdle is the current cost of making the dsRNA,” he says.

“However, there are companies now starting up to exploit economies of scale to get the cost down. The work undertaken by Professor Mitter and Xu is definitely changing how we look at controlling pests.”

The BioClay formulation involves suspending the dsRNA and clay matrix mixture in water and spraying the clear solution onto plants.

In proof-of-concept studies with tobacco plants in the glasshouse, one application of BioClay provided 20 days’ protection against tobacco mosaic virus, which amounts to a commercially viable period of time. Based on the clay degradation profile on the leaf surface, Professor Xu and Mitter believe that, with tweaking, the protective effect can be extended even more, up to 50 days. Field trials are underway to validate the findings.